- Active in current markets

- Wholesale distributor of chemicals

- Environmentally friendly chemicals

- Stockist, warehouse operator

- Awarded as an exporter

- Partner in the chemical industry

Information

Tanning

The Path to Refining Animal Hides

Tanning is an essential process in which animal hides are transformed into high-quality leather. During this process, the hides gain water and decay resistance by converting protein fibers into leather fibers — a transformation that cannot be synthetically reproduced. The quality of the final leather product depends largely on the raw material and the chosen tanning method. Properties such as strength, elasticity, water resistance, and surface characteristics — from stiffness to softness — are significantly influenced by the tanning process.

Traditional Tanning Methods

The history of tanning goes back thousands of years. The methods can be categorized into four main types, based on the tanning agents used:

- Vegetable Tanning (Bark or Red Tanning) This method uses vegetable tanning agents, such as extracts from bark, wood, leaves, and fruits. It is mainly used for heavy cattle hides. The result is extremely firm, durable, and robust leather that develops a distinctive patina with use.

- Oil Tanning (Fat Tanning) This method uses fats and fish oils, especially for hides from deer, roe deer, sheep, and goats. The resulting leather is exceptionally soft with an almost wool-like texture. It is durable and washable without losing its quality.

- Alum or White Tanning (Mineral Tanning) Alum stone is used mainly for treating furs of smaller animals. The result is light-colored, soft leather that is particularly supple and often used for delicate applications.

- Chrome Tanning (Mineral Tanning) Introduced in the 19th century, this method uses chromium salts. It is characterized by short tanning times and produces easily workable, soft leather with a fabric-like feel, meeting modern requirements.

Combined Methods and Modern Developments

In addition to the classic methods, combinations of these techniques are often used to achieve specific properties and to shorten tanning times through mechanical and chemical support.Vegetable-Tanned Leather — Natural Quality in Various Forms

Leather produced with vegetable tanning agents is known as vegetable-tanned leather. The methods include:- Drum Tanning: The leather is treated in rotating tanning drums, allowing for relatively short production times. The leather produced is relatively soft.

- Pit Tanning: The hides are tanned in several pits filled with tanning liquor, known as the “coloring process.” This method produces firmer leather.

- Traditional Pit Tanning: This traditional method takes several months to produce extremely durable leather.

Do you need support with chemical services?

Import and export

Exclusive chemical solutions for the highest demands

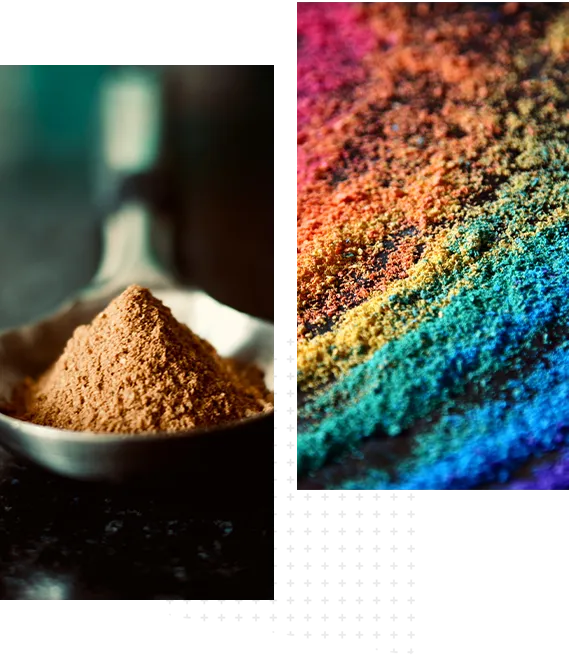

Tanning

Dyeing

Binders

Thermal insulation

Innovative solutions

We offer chemicals for a wide range of applications

25 +

Countries

80 +

Chemicals

117 +

Years

Our work process

Simple steps

Inquiry

Review

Import

Delivery

Experience our export products

We offer the best solution for your success

Trust Otto Dille – Your Partner for High-Quality Materials and Chemicals

With our decades of experience in the import and export of materials and chemicals, we offer you not only first-class products but also comprehensive services that simplify your processes. Thanks to our certifications and expertise, you benefit from streamlined customs clearance, transparent supply chains, and utmost reliability. We understand the specific requirements of your industry and develop customized solutions to efficiently achieve your goals.

Contact us today to learn how we can help you procure high-quality materials and chemicals easily and on time. Our team looks forward to advising you and successfully realizing your projects together.