- Active in current markets

- Wholesale distributor of chemicals

- Environmentally friendly chemicals

- Stockist, warehouse operator

- Awarded as an exporter

- Partner in the chemical industry

Information

LIGNINSULFONATE

Lignosulfonates – Versatile Applications in Industry

Lignosulfonates are natural polymers that are by-products of the pulp industry and are used in numerous industrial sectors. They find applications in the construction industry, chemical industry, agriculture, and animal feed production, and impress with their versatile properties.

Thanks to their dispersing, binding, and water-reducing properties, lignosulfonates play an important role in various processes. They serve as plasticizers for concrete to improve workability, as dust suppressants on unpaved roads and storage areas, as well as processing aids in leather manufacturing to optimize the softness and durability of leather products.

In agriculture, lignosulfonates are used as additives in fertilizers to enhance nutrient uptake by plants. In the animal feed industry, they are used as binding agents for pellets to increase feed strength and stability.

Thanks to their environmentally friendly and biodegradable nature, lignosulfonates offer a sustainable alternative to synthetic chemicals. Their use helps conserve natural resources and supports ecological processes.

As an experienced supplier, Otto Dille offers high-quality lignosulfonates for a wide range of industrial applications. We support our customers with expert advice and assist in selecting the optimal products to meet individual requirements.

WHAT ARE LIGNOSULFONATES?

Paper has existed for more than 2,000 years. The basic principle of its production has remained almost unchanged to this day: plant fibers are mixed with water, ground, cleaned, thickened, dispersed, and scooped up using a screen. The pulp is then pressed and dried.

The Chinese are considered the inventors of paper. They used bast fibers from the mulberry tree, China grass, and cotton as raw fiber material. It wasn’t until around 600 AD that papermaking spread to Europe via Japan and the Arab world. Around 1120, the first Italian paper mills were established near Genoa. The first trademark of paper, the watermark, was also invented in Italy. In Germany, Ulman Stromer founded the first paper mill near Nuremberg in 1390.

With Johannes Gutenberg’s invention of the printing press in the 15th century, the demand for paper increased significantly. As early as 1680, machines began replacing stamp hammers for pulp preparation. The so-called “Hollander beater” remained a central tool of the paper industry until World War II. In 1799, Louis Robert developed the mechanically driven screen — laying the foundation for modern paper machines. However, the decisive breakthrough came only with the industrial extraction of pulp from wood after 1860.

The role of lignin in the pulp industry

Wood, the primary raw material of the pulp industry, consists of cellulose, hemicellulose, and lignin. While cellulose and hemicellulose are well studied, lignin is a complex polymer made up of phenylpropane units. These form a three-dimensional network that is chemically bonded to carbohydrates.

Lignin is insoluble in neutral liquids and organic solvents. To separate cellulose, lignin, and other compounds, wood is treated with hot calcium, ammonium, sodium, or magnesium bisulfite solutions. During this pulping process, the lignin is sulfonated, producing water-soluble lignosulfonates.

Lignosulfonates / Kraft lignin

To produce pulp, the lignin must be dissolved out of the lignocellulose and removed from the process. Different methods are used for pulping and subsequent bleaching of the pulp.

About 80 percent of all pulp mills use the so-called sulfate process, also known as the Kraft process. Here, lignin is broken down by hydrogen sulfide ions (HS−) in an alkaline environment at about pH 13, using sodium sulfide (Na₂S) and sodium hydroxide (NaOH), or caustic soda. The process takes about two hours at temperatures around 170°C. However, the ions also attack the cellulose and hemicelluloses, resulting in only partial pulping. The black liquor from this process contains, in its solid matter, about 45% Kraft lignin when using softwood and about 38% when using hardwood.

An alternative is the sulfite process, where lignin is broken down by sulfonation. As a chemically undefined reaction product of lignin with sulfurous acid, lignosulfonates are formed — the salts of lignosulfonic acid. Calcium salts of lignosulfonic acid are produced when wood is treated with calcium bisulfite solutions. Here, the black liquor solid content is about 55% lignosulfonate for softwood and about 42% for hardwood.

Lignin is also responsible for the yellowing of paper, which is why it can be bleached using lignin-degrading enzymes like laccase. However, in industrial practice, bleaching is mainly done with chlorine-based methods or, more commonly today, “chlorine-free” bleaching using oxygen, chlorine dioxide, or, more rarely, hydrogen peroxide or ozone. In both cases, residual lignin and dyes in the pulp are oxidatively broken down. This is particularly relevant for so-called “wood-containing” paper and less so for “wood-free” paper. Although the terms wood-containing and wood-free are common in the trade and everyday language, technically they are inaccurate since paper made from wood always contains wood components. In wood-free paper, these are mainly cellulose and hemicelluloses, while wood-containing paper includes lignin-rich mechanical pulp. The more technically correct terms would be lignin-containing and lignin-free.

Properties and uses of lignosulfonates

Lignosulfonates exhibit different properties depending on their molecular weight. They mainly consist of lignosulfonates as well as hexoses and pentoses derived from carbohydrates. The hexoses are converted into alcohol by fermentation, while the pentoses are destroyed by chemical treatment. A low sugar content is crucial for the quality of lignosulfonates.

In recent years, the use of lignosulfonates as dispersing agents for aqueous dispersions has increased significantly. Their chemical structure, the ratio of hydrophobic to hydrophilic groups, and the molecular weight distribution determine their dispersing power.

Lignosulfonates have versatile applications, including:

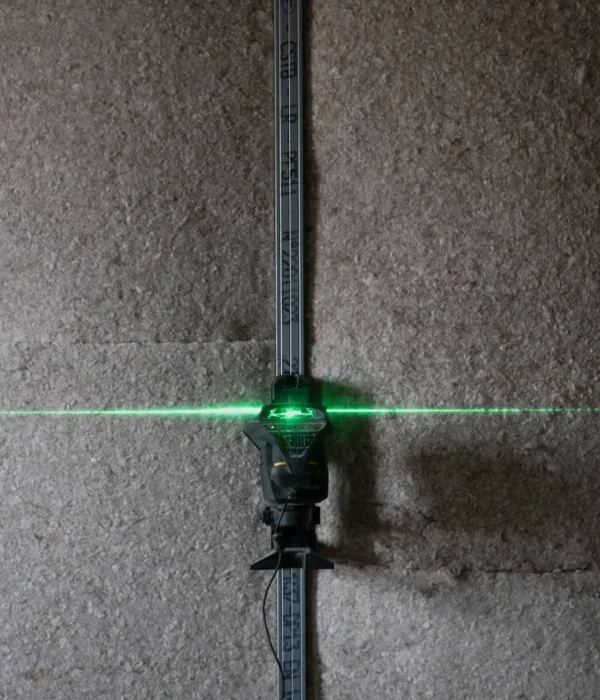

- Concrete plasticizer: Improves workability and reduces water demand.

- Dust suppressant: Prevents dust formation on roads and construction sites.

- Pellet binder: Stabilizes feed and fertilizer pellets.

- Leather industry: Acts as a softener and enhances leather durability.

- Drilling industry: Used as a lubricant and dispersant in drilling fluids.

Sustainability and future of lignosulfonates

Lignosulfonates are biodegradable and offer an eco-friendly alternative to synthetic chemicals. They help conserve natural resources and make industrial processes more sustainable. Thanks to ongoing research, new applications are being developed, especially in the field of biopolymers and sustainable materials.

As an experienced supplier, Otto Dille offers high-quality lignosulfonates for industrial applications. We support our customers with expert advice and help select the optimal products for specific requirements.

Do you need support with chemical services?

Import and export

Exclusive chemical solutions for the highest demands

Tanning

Dyeing

Binders

Thermal insulation

Innovative solutions

We offer chemicals for a wide range of applications

25 +

Countries

80 +

Chemicals

117 +

Years

Our work process

Simple steps

Inquiry

Review

Import

Delivery

Experience our export products

We offer the best solution for your success

How do lignosulfonates work?

As dispersants

The mechanism of dispersion formation or deflocculation is complex and the subject of extensive studies. In simple terms, the dispersion properties are related to the surface-active properties of the substances being processed.

Lignosulfonates are particularly used when particles need to be dispersed in water. By adsorbing onto the particle surface, they reduce interfacial tension and stabilize the suspension.

When particles are suspended in a liquid, an electrical double layer is formed, influenced by the following forces:

- Gravity

- London-van-der-Waals attraction forces, which act when particles are in close proximity

- Repulsive forces, caused by the electrical double layer

- Brownian motion, which keeps small particles in suspension

Lignosulfonates act as deflocculants by increasing particle stability through electrical repulsion, thus preventing settling.

As binders

A key property of lignosulfonates is their ability to bind particles. The exact nature of this binding—whether physical or chemical—is not yet fully understood, but it relies on intermolecular forces.

The binding strength is influenced by:

- Molecular size of the binder

- Polar groups, which enhance adhesion

- Side chains of the binder, which stabilize the bond

Due to these properties, lignosulfonates are suitable for numerous applications requiring strong adhesion.

As complexing agents

Lignosulfonates are effective complexing agents that bind metal ions to form stable, soluble complexes (chelates).

For particularly efficient separation processes, the combination of lignosulfonates with EDTA (ethylene diamine tetraacetic acid) is recommended. This combination offers an economical solution with high efficiency and excellent dispersion properties.

Where are lignosulfonates used?

Accumulators

Desulfonated, fractionated specialty lignosulfonates have long been used as expanders in negative pastes for lead-acid batteries. They ensure a controlled structure of lead sulfate deposits during discharge, significantly increasing cold-cranking capacity at high discharge rates.

It has also been found that the use of these modified lignosulfonates reduces polarization of the negative plates, extends service life, and increases discharge capacity.

Recycled paper

The corrugated cardboard industry—striving for more environmentally conscious production—already consumes more than half of the available recycled paper. However, paper and cardboard production still requires significant amounts of water, which should be kept as low as possible for economic and environmental reasons.

After years of testing, our products can be used as a substitute for starch (e.g., potato starch). The crosslinking properties of our lignosulfonates in the final drying stage are adjusted to ensure uniform processing, and any resulting breakage can be reintroduced into the production process without issues.

The best properties are achieved by mixing our lignosulfonates with starch in a 75:25 ratio (dry matter to dry matter), creating a synergistic effect that results in an increased CMT-60 value. Notably, the permeability of the produced paper and cardboard types remains unchanged.

In summary, the mixture of our lignosulfonates with starch increases coating density while reducing the amount of water needed during re-pulping in the production process, thus positively impacting production costs in two ways.

Drilling aids

Cost-effective drilling is hardly imaginable without highly modified ferrochrome lignosulfonates. Our lignosulfonates are used as highly effective dispersants for nearly all types of clay. Their high resistance to extreme pH values, temperatures, and pressures allows for universal application.

Our lignosulfonates act as a protective gel while evenly distributing all components in the drilling mud, achieving high stability.

Regardless of the type of saline solution, our lignosulfonates can be used in any drilling mud quality, whether seawater or freshwater, and are resistant to cement and chlorides.

Due to their high temperature sensitivity, our lignosulfonates can replace organic filter agents, which are typically less resistant to high temperatures.

In summary, our lignosulfonates do not alter the rheological properties of the drilling mud but partially compensate for the negative effects of high temperatures and pressures. Further technical information on this complex topic is available upon request.

Emulsions

Various lignosulfonates are used as highly effective and stabilizing products in oil-water emulsions. Regardless of pH, temperature, or oil-water ratio, these emulsions remain stable over long periods. Their ability to bind different types of fats enables their use in asphalt emulsions and environmental applications.

Ore flotation

Our products excel in this application due to their excellent dispersion properties, positively influencing both layered and rotational processes.

In the layered process, optimal distribution is achieved while preventing clumping and sticking. In the rotational process, uniform distribution results in a higher degree of separation, significantly increasing concentration.

Additionally, filtration properties are improved, minimizing moisture content in lead-zinc compounds. Our lignosulfonates also reduce the negative properties of calcium, barium, talc, graphite, and similar substances in the flotation process, performing similarly to quebracho.

Dyes/pigments

In the production and processing of organic textile fibers, auxiliary chemicals play a crucial role for various functions. Our specially developed lignosulfonates have positive effects on many issues, acting as dispersants, leveling agents, and anti-caking agents.

They also actively support the grinding process, where chemical reaction times can be either slowed or accelerated.

Selecting discs, as they maintain excellent dispersion properties at temperatures up to 250°C and pressures up to 60 bar.

Water desalination

Lignosulfonates are currently used successfully in seawater desalination. Our sodium lignosulfonates are mixed with sodium tripolyphosphate and an antifoaming agent. This chemical mixture prevents deposits inside evaporation systems caused by calcium, magnesium, iron salts, and organic materials.

Water-coal mixture

This mixture serves as a substitute for heating oil, achieving the same high combustion qualities. Our lignosulfonates act as dispersants for finely ground coal mixed with water. High demands are placed on the flow properties of this mixture without significant combustion losses. Global tests have proven that our lignosulfonates effectively replace heating oil, particularly during times of high crude oil prices.

Cement/concrete

Several of our lignosulfonates are ideal for reducing water content in cement production using the wet process. This reduction increases productivity, reduces effort, and saves costs in the drying process. In the dry process, their use as binders in granulation is also cost-effective. In concrete production, lignosulfonates reduce the required water content. Despite this reduction, our lignosulfonates maintain consistent viscosity, keeping the material flowable, and dispersions can be produced at any desired concentration. Our lignosulfonates offer the following advantages:

- Increased dispersion, leading to enhanced plasticization of the concrete mass

- Controllable drying and hardening times

- Increased density and flexibility

- Minimization of air inclusions due to improved flow properties

We also offer a product that can fully replace “sodium naphthalene,” achieving the same properties at significantly lower costs.

Important note

The mentioned examples of lignosulfonate applications do not cover all possible uses. All information and suggestions about our products are non-binding and provided without guarantee, though they are based on the best scientific research and industrial experience. For further information, please request our detailed informational materials. For specific needs, please consult our application engineers, who are available for precise process-related advice.